Advanced Fasteners and Machining Techniques for Custom Manufacturing

Advanced Fasteners and Machining Techniques for Custom Manufacturing

Blog Article

Grasping the Art of Fasteners and Machining: Technologies and Best Practices

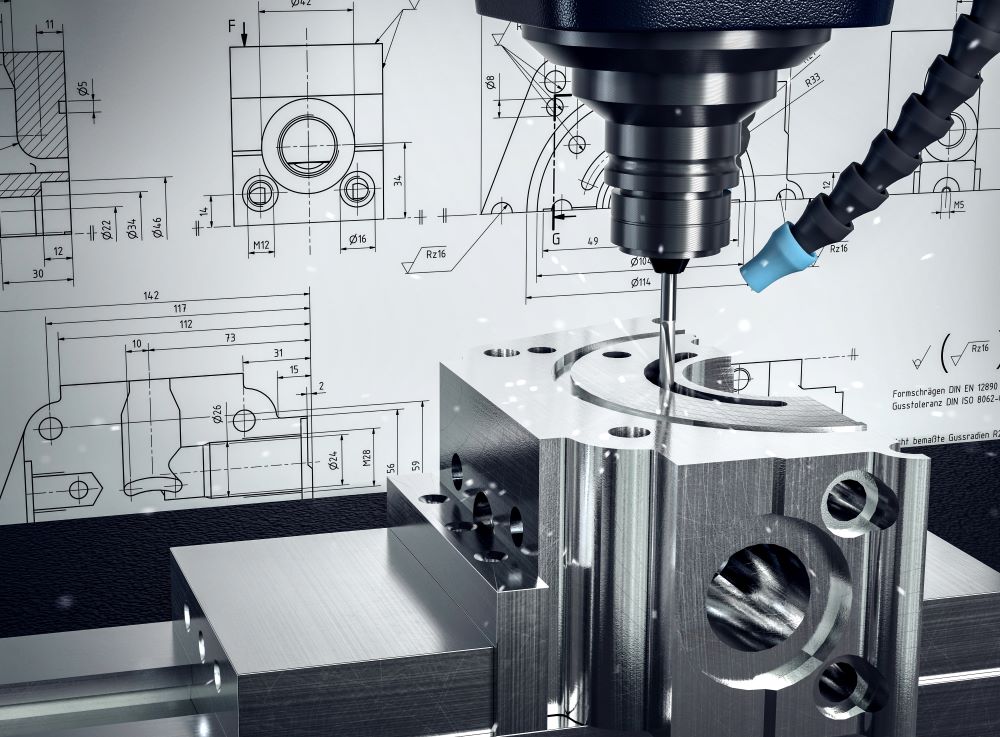

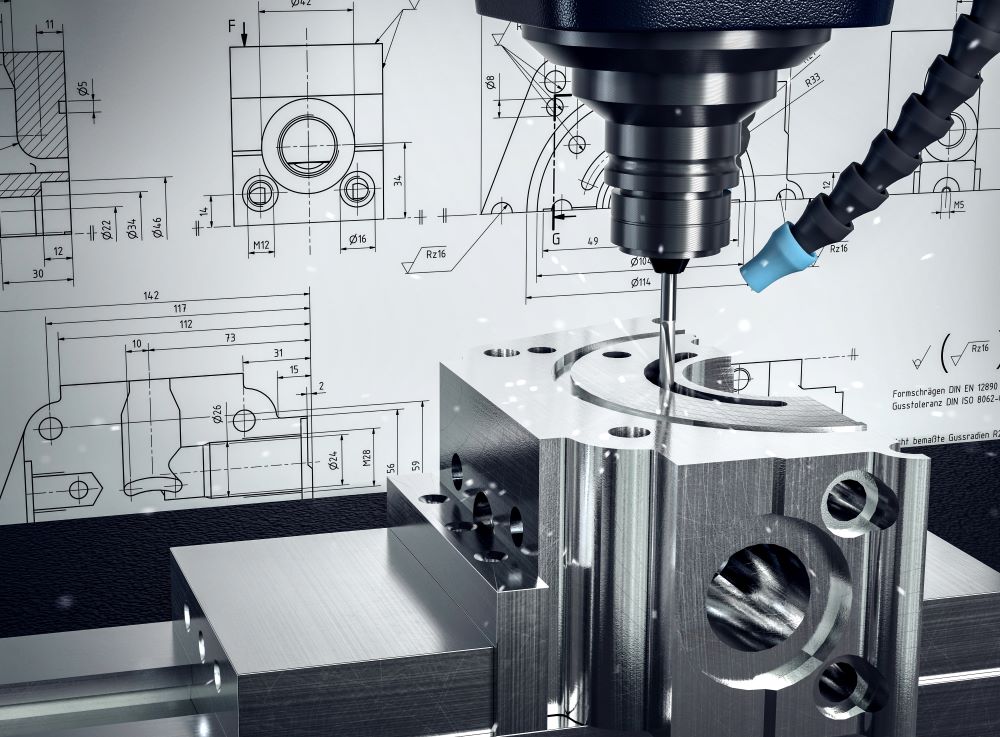

In the world of commercial production and design, the mastery of fasteners and machining is a keystone of ensuring architectural integrity, capability, and long life in numerous applications. Join us as we check out the newest advancements and dig into the nuanced world of grasping fasteners and machining, uncovering key understandings and approaches that can raise your strategy to engineering solutions.

Advancement of Attachment Technologies

Throughout the commercial revolution and right into the contemporary period, the evolution of attaching modern technologies has actually been noted by constant improvements in performance and dependability. Fasteners, such as rivets, screws, and screws, play a critical role in different markets, including vehicle, aerospace, building and construction, and electronic devices. The requirement for more powerful, a lot more resilient, and easier-to-install attachment solutions has actually driven technology in the field.

One substantial growth has actually been the shift towards accuracy machining techniques to produce bolts with higher resistances and superior efficiency. This change has actually allowed suppliers to create bolts that fulfill stringent top quality standards and deal increased resistance to rust and exhaustion.

In addition, the intro of sophisticated materials, such as titanium alloys and compounds, has revolutionized the capabilities of fasteners. Fasteners and Machining. These materials provide extraordinary strength-to-weight proportions, making them ideal for applications where reducing weight is critical without compromising architectural stability

Improvements in Machining Methods

In the world of industrial manufacturing, the constant development of machining methods has actually led the way for unprecedented precision and efficiency in the manufacturing of fasteners. One of the significant improvements in machining methods is the application of Computer Numerical Control (CNC) innovation. CNC machines use unparalleled accuracy and repeatability by enabling automated control of machining devices. This precise control enables manufacturers to create complicated and intricate bolt styles easily.

Furthermore, the adoption of multi-axis machining centers has allowed simultaneous cutting operations from different angles, additionally improving effectiveness and lowering production times. By using these sophisticated machining approaches, producers can meet the enhancing demand for premium fasteners while preserving cost-effectiveness in their procedures.

Selecting the Right Bolt Materials

Picking the appropriate material for bolts is an important choice that considerably affects the efficiency and durability of the put together components. When picking the right bolt product, a number of elements must be pop over to these guys considered to ensure the longevity i loved this and integrity of the last product. The product selected ought to be suitable with the environmental conditions the fasteners will be subjected to, such as temperature level variants, dampness levels, and corrosive elements.

Common materials made use of for fasteners consist of stainless steel, carbon aluminum, titanium, and steel, each offering special buildings that fit various applications. Stainless steel, for instance, is understood for its corrosion resistance, making it ideal for aquatic or outside settings. Carbon steel is an affordable choice suitable for several general-purpose applications. Aluminum is lightweight and usually utilized in markets where weight is an essential element. Titanium, on the various other hand, is remarkably strong and corrosion-resistant, making it appropriate for high-performance applications.

Enhancing Accuracy in Machining

Attaining ideal accuracy in machining is important for making sure the top quality and performance of machined elements. To improve precision in machining, producers use a range of advanced strategies and technologies.

In addition to CNC machining, the use of sophisticated cutting tools and tool holders can additionally significantly improve precision. Premium cutting tools with advanced coverings lower friction and wear, leading to much more precise cuts and dimensional accuracy. Additionally, applying rigorous quality assurance procedures throughout the machining procedure, such as normal evaluations and calibration of equipment, assists keep consistent accuracy degrees. By focusing on precision in machining, makers can attain superior item quality, tighter resistances, Visit Website and boosted overall performance of machined parts.

Finest Practices for Fastener Installation

Precision in machining plays an important role in making certain the dependability and long life of fastener installations. One key aspect is the correct option of bolts based on the particular application demands when it comes to ideal techniques for fastener installment. Using the right kind, dimension, and product of fastener is necessary to ensure ideal performance and durability. Fasteners and Machining. In addition, it is critical to follow supplier guidelines and advised torque values during the installment procedure to stop over-tightening or under-tightening, which can result in premature bolt failure.

Additionally, making sure that the fastener threads are clean and totally free of particles prior to installment is vital to achieving a safe and secure and effective connection. Making use of thread-locking substances or washers can likewise enhance the security of the bolt setting up. Routine examinations and maintenance of bolts post-installation are suggested to recognize any type of potential problems early and stop costly repair work or substitutes in the future. By adhering to these best methods, makers can maximize the honesty and performance of their bolt installments.

Conclusion

To conclude, the advancement of attaching technologies and improvements in machining methods have significantly enhanced the effectiveness and effectiveness of bolt setup procedures. By picking the right fastener materials and improving precision in machining, producers can attain ideal outcomes in their operations. Adhering to finest methods for fastener installment is essential in making sure the resilience and dependability of assemblies. In general, understanding the art of bolts and machining entails continual innovation and adherence to best techniques.

In the world of industrial production, the continual advancement of machining techniques has led the means for unprecedented precision and efficiency in the manufacturing of bolts.Accuracy in machining plays a crucial role in making sure the dependability and durability of bolt installments. When it comes to finest methods for bolt installation, one crucial facet is the correct option of bolts based on the particular application demands. By selecting the appropriate bolt products and boosting precision in machining, producers can achieve optimal results in their procedures. On the whole, understanding the art of fasteners and machining includes continual advancement and adherence to best techniques.

Report this page